Companies all over the world are fighting to survive in today’s highly competitive economy. To survive, companies must strive for operational excellence where each and every employee can see the flow of value to the customer, and fix that flow when it breaks down.

Operational Excellence through implementation of Lean offers a proven method to eliminate waste, increase productivity, and improve profitability while maintaining the high levels of quality and service customers expect.

Lean is a proven system that can be used not only in manufacturing and assembly plants but also other sectors including hospitals and laboratories, construction, offices, and retail distribution.

Lean is a way of thinking and executing that improves processes through continuous improvement and elimination of waste. Lean requires top-down commitment and bottom-up involvement.

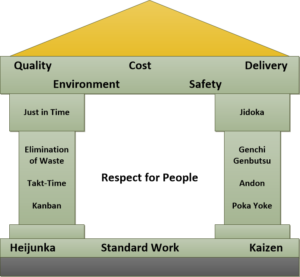

Many of the modern methods used in lean manufacturing were pioneered by Toyota in the Toyota Production System (TPS). The foundations of Lean are built on leveling of production (heijunka), standard work, and continuous change for the better (kaizen). Building upon this foundation are two main pillars which represent “Just-in-time production” (JIT) and “Automation with a human touch” (jidoka).

Just-in-time production means only making what is needed, when it is needed and in the amount needed. Automation with a human touch signifies that machines are designed in such a way that they can detect errors when processing and have the ability to stop the process.

Just-in-time production means only making what is needed, when it is needed and in the amount needed. Automation with a human touch signifies that machines are designed in such a way that they can detect errors when processing and have the ability to stop the process.

The two pillars are joined by a respect for humanity which means staff and associates are respected and viewed as valuable contributors to the process.

Applying Lean principles can greatly improve efficiency as well as quality. A key aspect of this system is the building of quality into the process; do not pass a defect on to the next process (upstream customer). Through application of this fundamental rule, problems are highlighted immediately and addressed quickly.

To learn more about how your company can achieve Operational Excellence through lean, select a category on the right and start learning about the various aspects of this system. It could literally change the way your company competes.